Which Electrical Copper Wire Manufacturers is Best for Home?

Electrical Copper Wire Manufacturers a variety of copper wire products from different electrical copper wire manufacturers. These companies have a wide selection of copper wire products and can also provide you with the best prices possible. In this article, you’ll learn how to choose the right copper wire for your electrical projects. By the end of the article, you’ll have a better understanding of what each one has to offer. Whether you need bare copper wire, tinned copper wire, or PVC-insulated copper wire, you’ll know which type to purchase.

Types of Copper Wire:

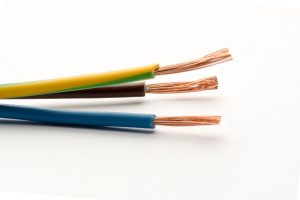

In addition to electrical wiring, bare copper wires have a number of uses in the electrical industry. These wires are used for busbar crafts, electrical grounding applications, and metal finishers’ hanging wire. Bare copper wires are made from solid, soft-drawn annealed copper and meet ASTM-B-3 and QQ-W-343 standards. They are available in a variety of sizes and are typically packaged in spools of five, fifteen, and 45 pounds.

Bare copper wires are the most common type of wire used in electrical wiring and electronics. They are unalloyed and have the highest conductive properties of all wire types. They are usually used for overhead transmission, distribution, and uninsulated hook up. There are two types of bare copper wire: tin-coated bare wire and untinned tinned wire. Both materials have similar electrical properties, but bare copper is the most durable.

Tinned Copper Wire:

There are many different types of Tinned Copper Wire, including multi-strand, stranded, and electrolytic types. These wires are available in many different colors and densities. Tin is an extremely common element used in these wires and adds to their conductive properties. Tin-plated copper wires are highly corrosion resistant and are ideal for use in many different applications. Tin-plated copper wires are usually used in conductive cores, outer shielding braiding layers, and brush wires for cables.

Electrical Copper Wire Manufacturers are generally higher in price than their bare counterparts, but the benefits outweigh the costs. They last significantly longer than their bare copper counterparts and are easier to solder. In addition to the corrosion protection that tinned wires offer, tinned wires are also much easier to solder than bare copper. These advantages make tinned wires a great choice for electrical wiring in a wide range of applications.

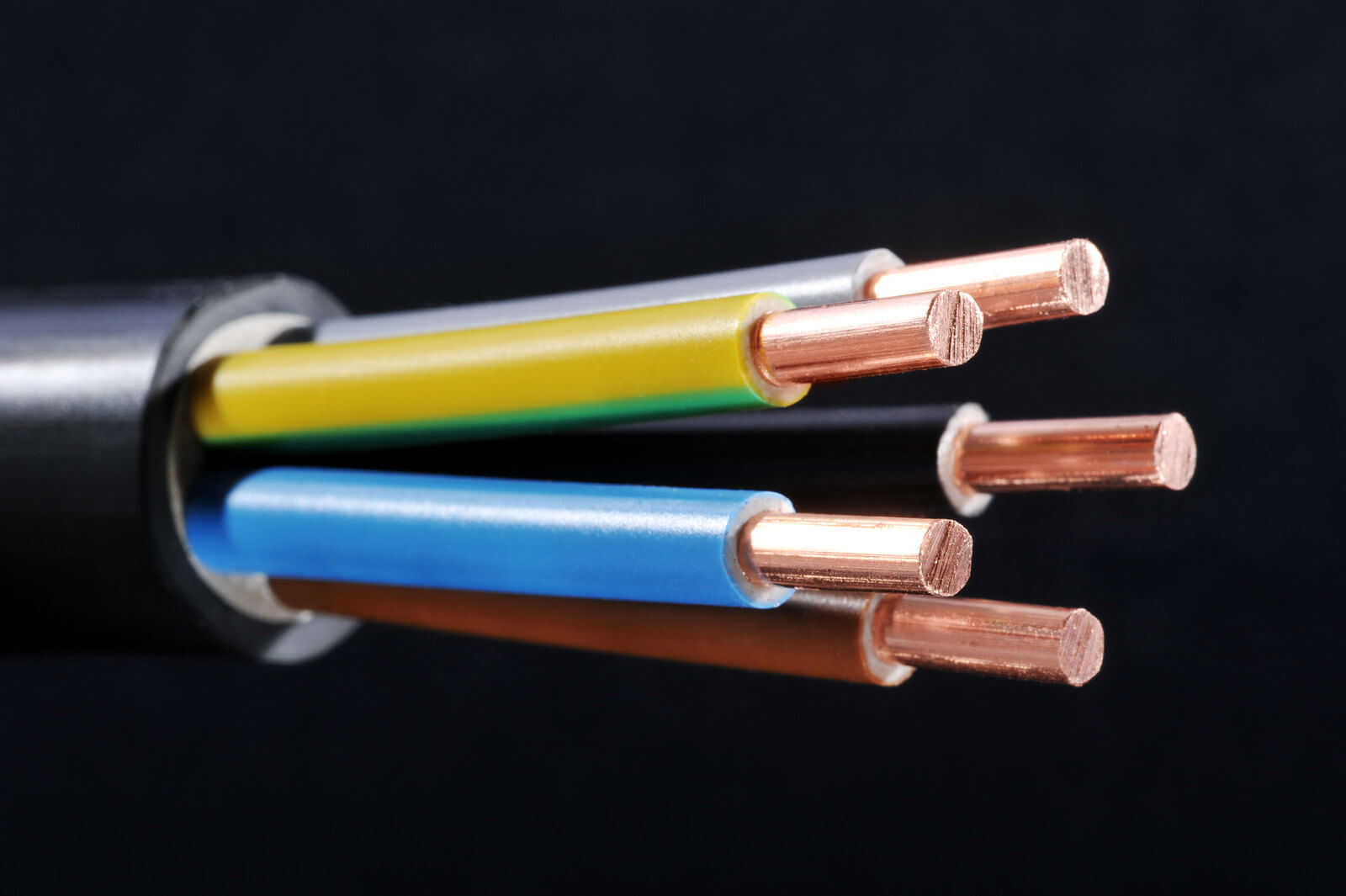

Insulated Copper Wire:

You can purchase insulated copper wire at several places. Try doing a Google search for insulated copper wire manufacturers in your area. You should choose suppliers who can offer high-quality insulated wire at competitive prices. Generally, prices increase as a commodity moves through the supply chain, so you might be better off buying directly from the manufacturer. Here are some tips to help you choose a reliable supplier:

Find out about the company’s production infrastructure and quality inspection processes. Ideally, insulated wire manufacturers will have a production infrastructure and stringent quality controls. You should choose a company that is headquartered in a country where the insulated copper wire is used. Insulated wire manufacturers are located throughout the country. This article provides some general information on the manufacturing process and the different types of insulated wire available in the market. However, you should also look for a company that has its own research and development team.

PVC-Insulated Copper Wire:

If you are looking for suppliers of PVC-insulated copper wire, you are in luck. You will find many of these companies listed on EC21, the largest B2B marketplace. Manufacturers list their products for free, and you can browse their offerings to find what you are looking for. The following are some things to keep in mind when choosing a supplier of this wire. EC21 is a great place to find a supplier of this type of wire and other types of insulated copper wire.

There are various types of insulated copper wires on the market, including single-core and multi-core. Each type has its own unique properties, such as varying temperature and voltage ratings. You can find UL-approved wires and those that have CSA approval. Many of these wires are suitable for applications up to 300 volts and are resistant to fungus, solvents, oils, and chemicals.

Is Copper Wiring Better Than Aluminum?

If you are looking for an electrical copper wire manufacturer, you will find several options in the following article. Enameled copper winding wire, Flat, Square and Triangle, and stranded copper wire will be discussed. Then, you can learn more about the process used to make these products. And, if you have any questions, you can always contact one of the companies listed below. Here are some of their features:

Electrical copper wire manufacturer’s supply enameled copper winding wires with exceptional physical and mechanical properties. These wires have an excellent cut-through performance, are direct-weld able, and resist high frequency and electronics corona. The electrical wire manufacturers also offer a large variety of enameled copper wire grades. The quality of the copper used for enameled wires depends on the manufacturer’s manufacturing processes, as well as the materials used.

The industry has a unique financial attribute, which makes the development of copper products directly related to the national economy. This cycle also matches the development of the industry. The development of enameled wire will follow the direction of the downstream industry, and the demand for high-end products will increase. Further, the degree of market concentration will increase, and the concentration will become more uniform. The downstream industry will eventually become more competitive, and small and mid-sized enterprises that can’t meet the demands of the market will be eliminated.

Flat Copper Wire:

Flat copper wire manufacturers specialize in producing these products in a variety of formats. Their capabilities include a variety of cross-sectional shapes and absolute control over key parameters. The flexibility of flat wire products is improved in high-flex applications, such as high-end instruments and mechanical components. Moreover, flat wires eliminate the need for fastening and locking during installation. The following are the benefits of flat copper wire. If you are in the market for flat copper wire, you can contact a Flat copper wire manufacturer today.

Justdial is a handy tool to choose Flat Copper Wire Manufacturers in Bangalore. Search for businesses in Bangalore using factors like location, popularity, ratings, and reviews. Then, fill out the Best Deals tab to request a quote. Businesses will contact you with their best offers. You can even chat with them and receive multiple quotes in a matter of minutes with the JD Android app. For the best deals, choose the one that offers the best deal.

One of the benefits of copper square wire is its low cost. Square wire manufacturers offer a wide variety of sizes, including standard, custom and specialty shapes. Common wire shapes include flat, round half, square, triangle and diamond. Some of these wires are designed for electrical applications, fasteners, surgical instruments, and musical instruments. Some manufacturers offer custom wire shapes, including wires with multiple strands or twisted strands.

The following is a list of some of the top copper wire producers. The details of the businesses include the name, address, and personnel. For instance, Algonquin Industries is a top producer of enameled wire for the automotive, motor, generator, and transformer industries. The Encore Wire Corporation in West Chester, Ohio, which specializes in designing the highest-quality wires for the healthcare, aviation, school construction, oil, and automotive industries, is another well-known producer of copper wire.

Conclusion:

Triangle intends to finance the acquisition with $70 million in corporate general funds and the rest through the sale of securities and debt. Both have a vested interest in them. Peter W. May, president, and CEO, own almost 14 percent of the company. In addition to their ownership stakes in Triangle, they are also controlling Avery Inc., which mines and distributes coal. They produce wire in various materials, including copper, nickel alloys, carbon steel, and stainless steel. These wires are used in a variety of applications, including fasteners, medical devices, and optical, musical, and lighting devices. The wires meet ASTM and ANSI standards and are RoHS compliant.